Every so often I write a post about one of my hobbies, of which I have several. Often I share a few images of myself actually doing the hobby however with my shooting-sports I often share some element of it that doesn't actually relate to the act of shooting at all, more something of a technical nature. Here's one of those posts which outlines the process of cleaning spent cases prior to the case-preparation and reloading stage. [Reloading relates to turning empty cases and the other components into ammunition.]

I use a wet-tumbling process to clean the cases. It can be done in other ways but in my opinion this is the best. Once the old primer is removed the dirty cases are simply tumbled in water, an acidic product called Lemi-Shine, dish washing detergent and stainless steel tumbling media. It's a very simple process which I've outlined below.

Why clean the empty cases

Cleaning them is not really about the look of the brass; It's more about removing carbon fouling from the inside, outside and primer-pocket of the case to leave a perfectly clean case to reload. It also means my expensive resizing die is kept in better condition through lack of fouling. The fouling comes from the gun powder exploding during the firing process of the round. I clean all of my spent cases, both rifle and handgun, for this reason. Below you can see the dirty and clean case comparison in image one.

The tumbler

I use a Rebel 17 tumbler which consists of a drum and base unit: Rollers and a motor essentially. One end of the drum comes off allowing it to be filled then a seal, the lid and six retaining nuts hold the lid down for the tumbling process. Image two and three show this clearly.

The media

This is simply a very fine stainless steal pin-media, blunt at both ends. In the tumbling process the media rolls around the case, inside and out, dislodging the carbon-fouling and the detergent and acidity of the Lemi-Shine help to loosen off the fouling.

The process

It's a fairly lengthy process, and not one I like doing in the cold as I always seem to get wet however it's an essential element of the reloading process. It takes about 4-5 hours all up to complete from putting the cases into the drum to drying them but in between there's no hands-on effort required. It's a set and forget process really, except for the pre and post tumbling elements.

Image one - A side-by-side image of the brass prior to and post-cleaning. You can clearly see how dirty they are and if you look carefully on the left you'll note the flash-burn in the primer pocket - This happens when the primer explodes into the case itself, which in-turn ignites the gun powder. For precision rounds I like a nice clean primer-pocket. The right image is the completely clean case.

Image two - Here you can see the process of setting up the tumbler with all the elements. The stainless steel pins are very small as you can see on the left. The middle image shows the dirty brass and stainless steel media in the tumbling barrel and the right image shows the amount of Lemi-Shine I use. You can also see the posts on the drum that retain the lid.

Image three - After the Lemi-Shine, detergent, dirty brass and stainless steel are all added it's a simple matter of filling it up with water to one inch below the lip. The middle image shows the base of the Rebel 17, the rollers and motor plus the Lemi-Shine and detergent which is a household dish washing variety. You can also see the retaining nits that hold the lid secure. The right image shows the barrel or drum on the base. A flick of the switch starts it turning and I leave it on for 2-3 hours depending on how much is in there.

Image four - Once the tumbling process is complete the drum is opened and the water emptied. The water is always very dirty, quite black in fact. I decant the cases including the stainless steel media into a bag, a paint-strainer bag to be precise, then rinse them thoroughly in a couple of buckets of clean water. The first of these contains some bicarbonate soda powder which stops any acidity from the Lemi-Shine acting any further.

The cases are then emptied into the media-separator which you can see above. The lid is closed and the handles turned for a few minutes which removes the stainless steel pins. They simply fall into the bottom of the grey tub you see to be collected later and reused. The cases are left in the slotted tumbler as you can see in the top right image.

Image five - Once separated from the tumbling media I empty the cases onto an open towel stolen from the linen press (shh, don't tell Faith), and I give them a bit of a pat down to dry them slightly. They are then loaded into food-dehydrator trays and into the dehydrator itself. This is done to make sure they are completely dry inside and out. Some people put them in a warm oven but I prefer the dehydrator which I set at 68 degrees. I usually leave them in there for an hour or so to ensure they are very dry, inside and out. After this is done they are left to cool and packed away for the next stage.

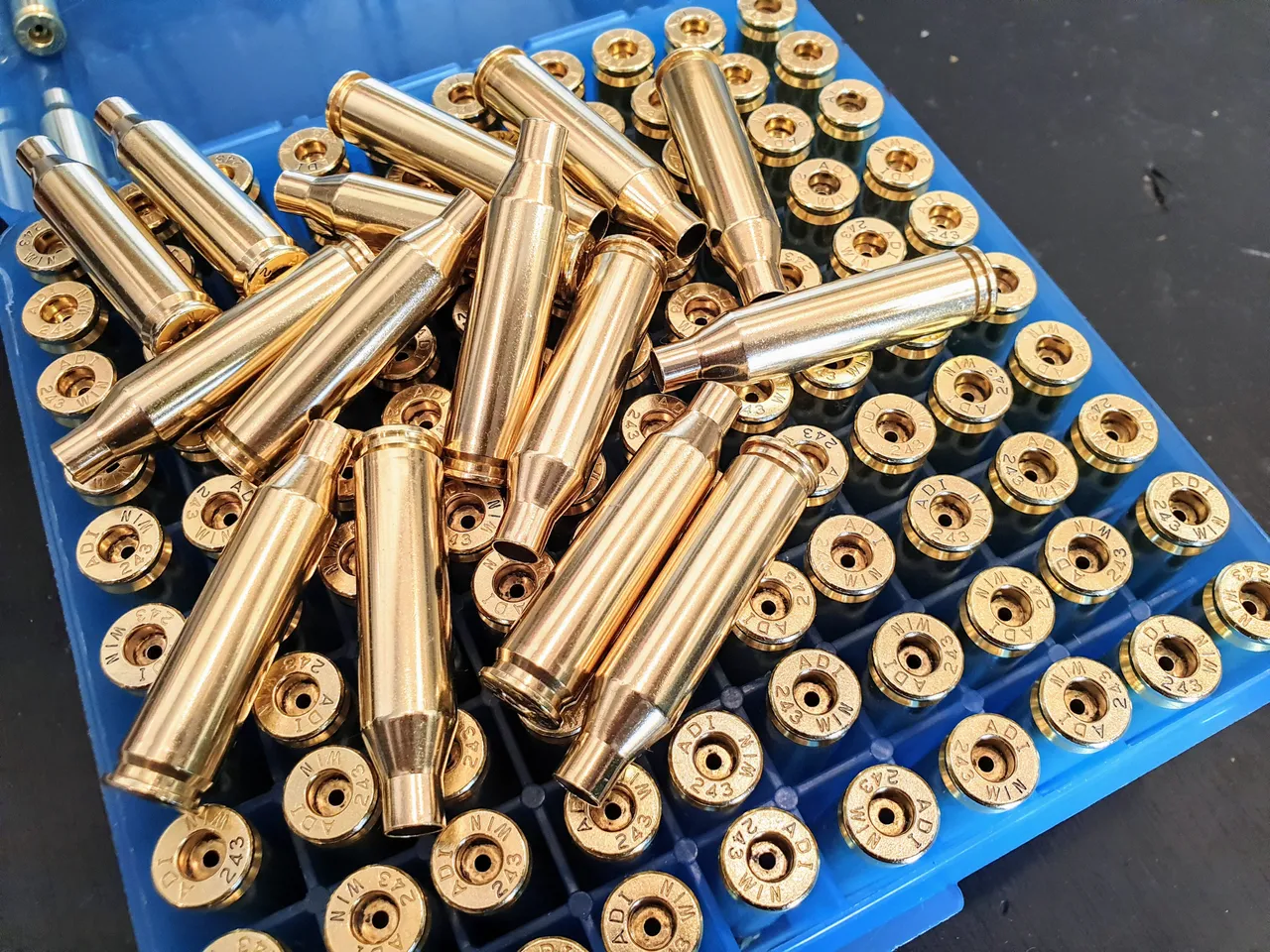

Image six - The finished brass cases ready for resizing back to factory specification, measuring and trimming, chamfer and deburring, priming and then reloading with gun powder and projectile ready for use.

The cases you see above, about 117 of them I think, will move on to the next reloading stage after I get back from New Zealand in a few weeks. Once loaded it'll mean I have around 500 of these rounds prepared. They are my culling rounds and I'll not need that many in a year although I shoot a couple of competitions per year at the range so 500 is about what I'll use, all up, in a year give or take. Of course this is just for this particular calibre. I used 400 9mm rounds over Saturday and Sunday just past so I'm always performing one element of reloading or the other...I guess that just comes with the territory of being a sport shooter.

Anyway, I hope you found this interesting. Again, this post is my attempt at showing that my sport-shooting and shooting in general, is not just a drunk dude shooting beer cans. A lot of effort goes into what I do, a lot of money also, and these together with a specific skill-set, and a lot of understanding, means I can continue my sport and culling work through a steady supply of precision-made ammunition.

Design and create your ideal life, don't live it by default