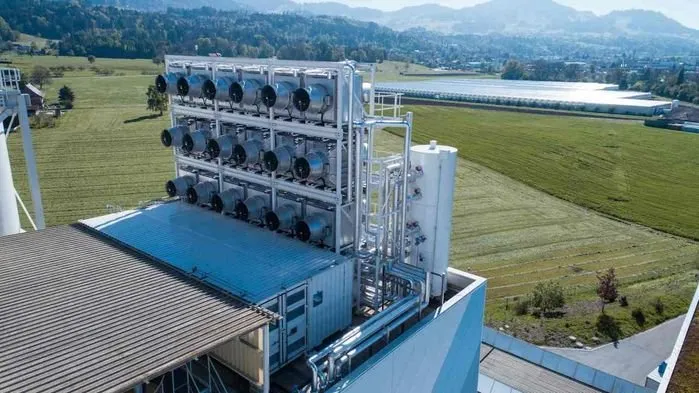

Just outside of Zurich, a company called Climeworks AG has become the first ever company to remove CO2 from the air and then sell it to a buyer. Estimates are that the machine will remove 900 tons of CO2 anually - roughly the amount produced by 200 cars in a year - and pipe the gas to customers who grow vegetables. This achievement has reopened the debate about whether technology can play a significant role in removing greenhouse gasses from the atmosphere.

Although the amount of CO2 captured at this plant is but a small fraction of what is released by fossil fuel plants, Climeworks sees this as a first step towards their goal of removing 1% of all the CO2 globally. In order for them to achieve this they estimate that they would need to construct another 250,000 similar plants!

At this plant the CO2 is sent to a greenhouse. In greenhouses farmers carefully control the environment to create perfect conditions for growing crops. By raising the CO2 levels within these greenhouses, the rate of photosynthesis is increased which can boost the crop yield by up to 20%.

"Highly scalable negative emission technologies are crucial if we are to stay below the 2-degree target (for global temperature rise) of the international community," said Christoph Gebald, co-founder and managing director of Climeworks.

How does it work?

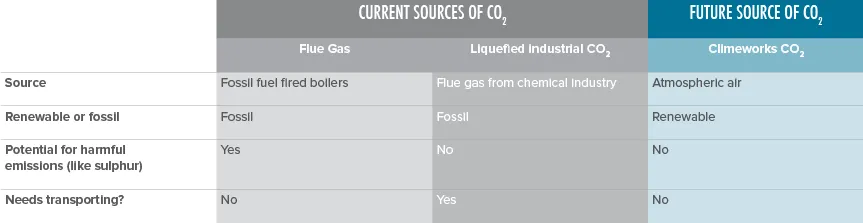

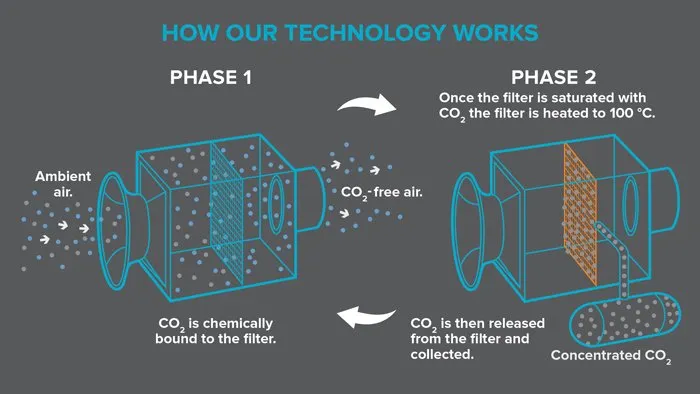

The plant is constructed above a heat recovery facility which powers the process. Fans push air through filters which collect the CO2, and once these filters are saturated the CO2 is separated by heating the filters to above 100°C. The gas is then sent via an underground pipeline to the customer. In this case it is sent to a greenhouse which grows fruit and vegetables like cucumbers and tomatoes. However the gas could be used in various other industries, for instance carbonating beverages.

“You can do this over and over again,” said Climeworks co-founder Jan Wurzbacher to Fast Company. “It’s a cyclic process. You saturate with CO2, then you regenerate, saturate, regenerate. You have multiple of these units, and not all of them go in parallel. Some are taking in CO2, some are releasing CO2. That means that overall the plant has continuous CO2 production, which is also important for the customer.”

Sideshow

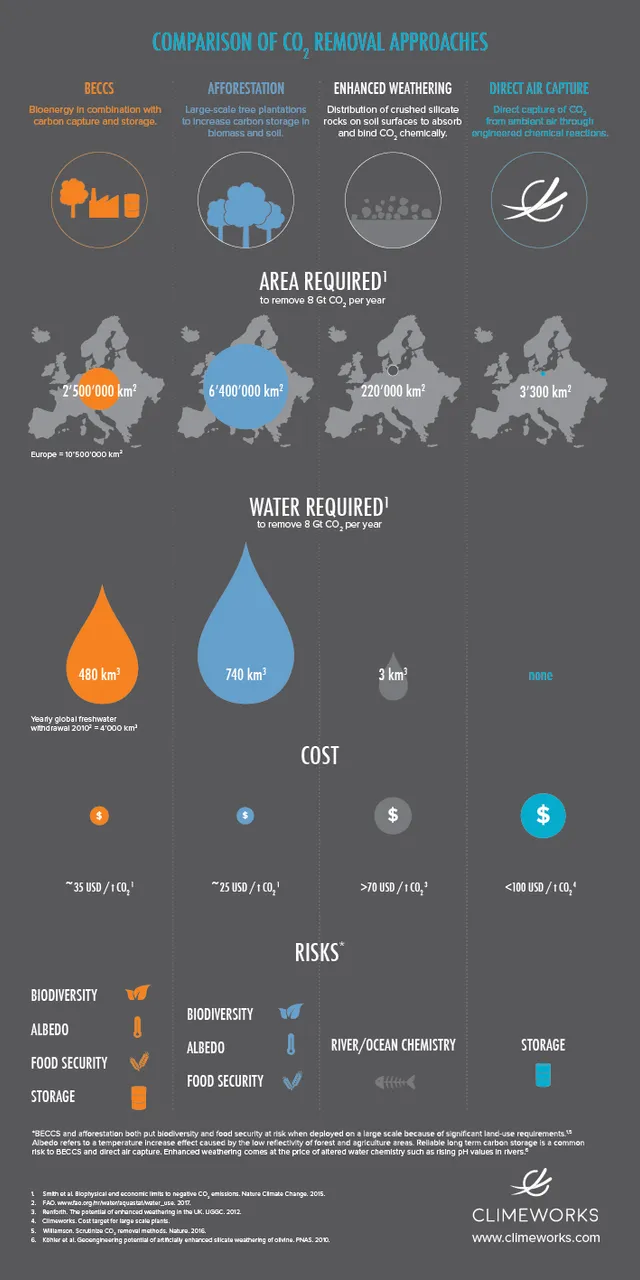

Critics of air capture technology say that it would be much cheaper and far more efficient to perfect carbon capturing directly at fossil fuel plants and prevent CO2 from getting into the atmosphere in the first place. Senior research engineer at MIT Howard Herzog says "At that price, it is ridiculous to think about right now. We have so many other ways to do it that are so much cheaper." He noted that the cost for air capture is so high partly because the CO2 is diffused in the air, whereas at fossil fuel plants it is far more concentrated and flows in a direct stream.

In 2015, the National Academies of Sciences, Engineering and Medicine released a report saying climate intervention technologies like air capture were not a substitute for reducing emissions. In 2016 it was written in the journal Science that air capture technologies are an "unjust gamble" and take focus away from more viable options for cleaning the air.

Supporters say that it is simply a matter of lowering the costs. More than a decade ago, entrepreneur Richard Branson launched the Virgin Earth Challenge and offered $25 million to the builder of a viable air capture design. Climeworks was a finalist in this competition.

Personally I believe that any step is a step in the right direction when it comes to tackling climate change, and as technology evolves and more efficient combat techniques are found, a huge difference can be made. The irony of it all is that we as humans put all the excess in the air in the first place with technology!

If you enjoyed this post please upvote, resteem and follow me @ollie7!!!

Sources:

http://www.sciencemag.org

http://www.climeworks.com

http://www.bigthink.com

http://www.republicworld.com