The Process Of Making Silica Xerogell

Silica gel is a form of silica produced by the coagulation of sol sodium silicate (NaSiO2). This gel-like solvent can be dehydrated so that it turns into a non-elastic glass-like solid or granular. This property makes silica gel used as absorbent, drying, and catalyst support. Cobalt salts can be adsorbed by this gel. Silica gel prevents the formation of excessive moisture before it occurs. The sol-gel process has been widely developed primarily for the manufacture of hybrids, the combination of inorganic oxides (especially silica) with alkoxysilane.

This process is based on molecular precursors that can undergo hydrolysis, mostly metal or semi-metal alkoxides. Especially for the manufacture of hybrids, combinations of inorganic oxides (especially silica) with alkoxysilane. This process is based on molecular precursors that can undergo hydrolysis, mostly metal or semi-metal alkoxides.

The sol-gel process can be described as forming an oxide web through progressive polycondensation reactions of a precursor molecule in a liquid medium or is a process for forming the material through a sol, gelation of the sol and ultimately forming a gel.

Step by Step Making Silica Xerogell1

Ash of Bagasse

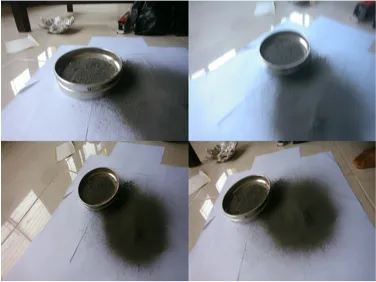

Provide less then 100 gram of Bagasse

Smooth with 80 mesh sieve

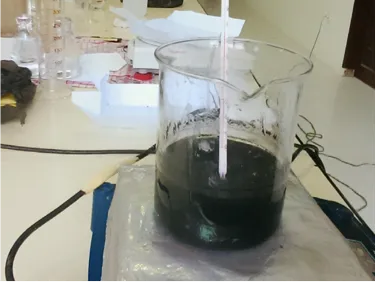

Provide NaOH (Sodium Hydroxide)

Mix both Bagasse and NaOH electric heating until boil away till solvent vicous.

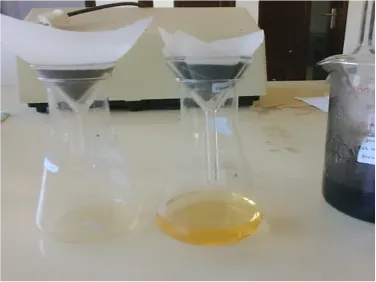

Take it and get it warm, then squeeze to get Sol Sodium Silicate ( Yellow Liquid)

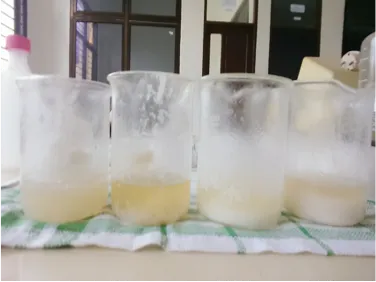

Pour into beaker glass

Dry in open until all water is boil away

After water boiled away.

Now its time to mix it with acid

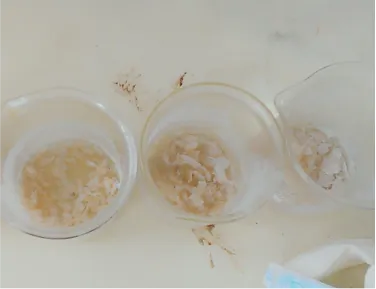

after 24 hour

Pour in pocelain cup

You have made a Silica Gell, Then Next step we continue how to make silica xerogell. i will continue in part 2.